“And above all, watch with glittering eyes the whole world around you because the greatest secrets are always hidden in the most unlikely places. Those who don’t believe in magic will never find it”

Completing a project in my shop usually plays out like this: first, I dance around and scream “It’s finished, it’s finished!” as loud as I can. I’m ecstatic that I managed to finish the damn thing so I can move on to something else. Once I realize that no one else in the house actually cares, I stop screaming and start to feel a little sad. I’ve invested a lot of effort and emotion into the project which can make it difficult to move on.

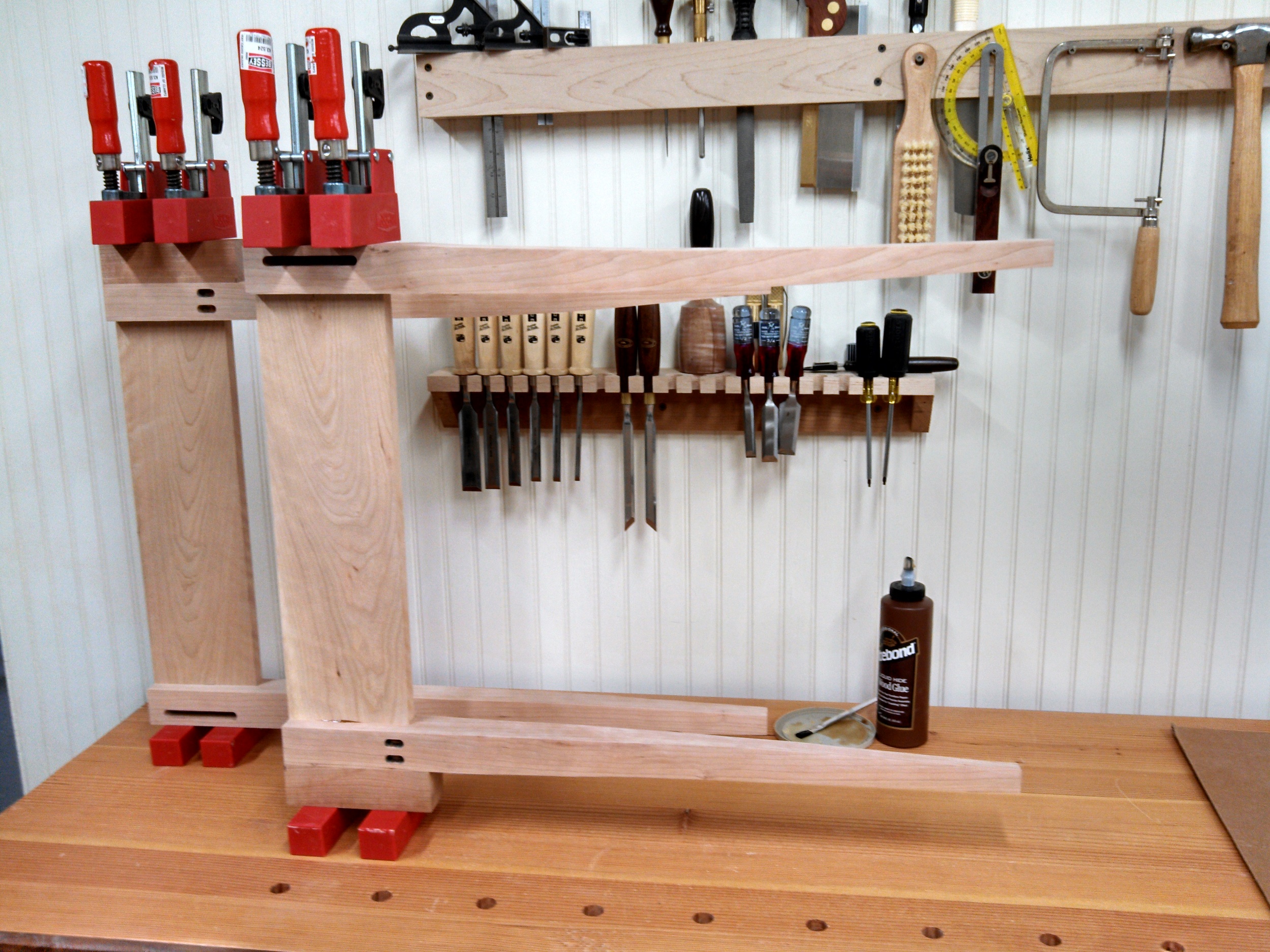

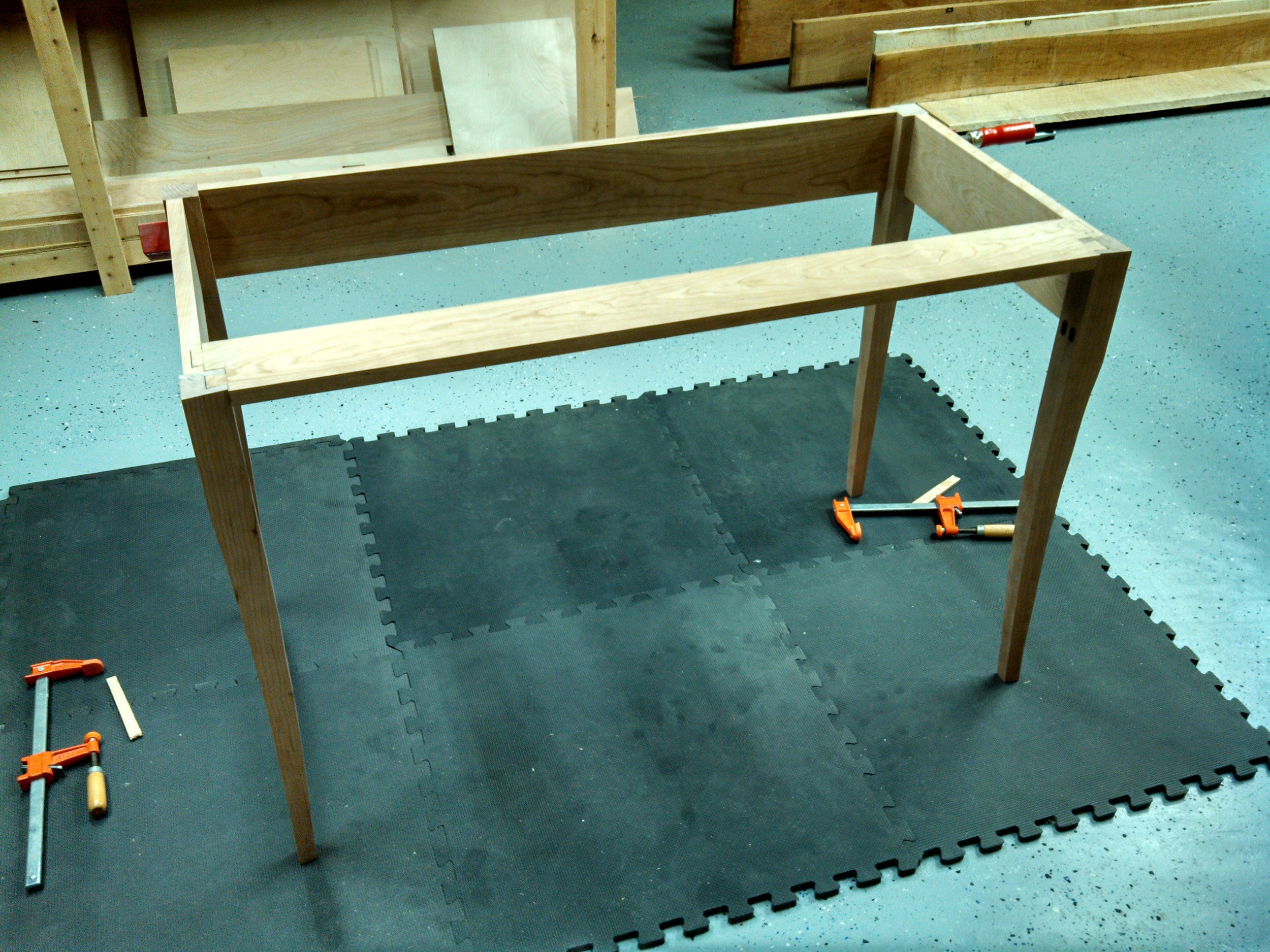

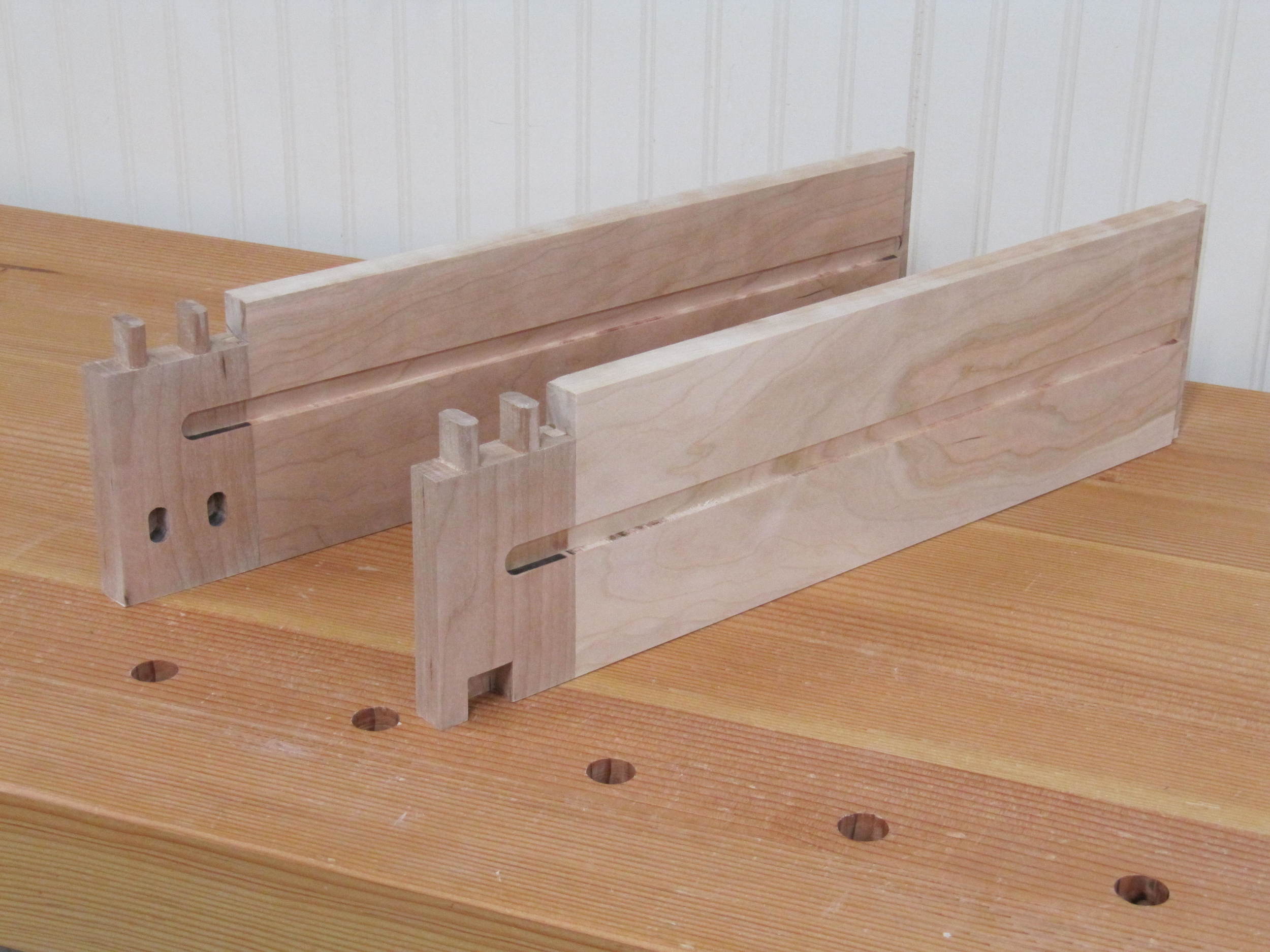

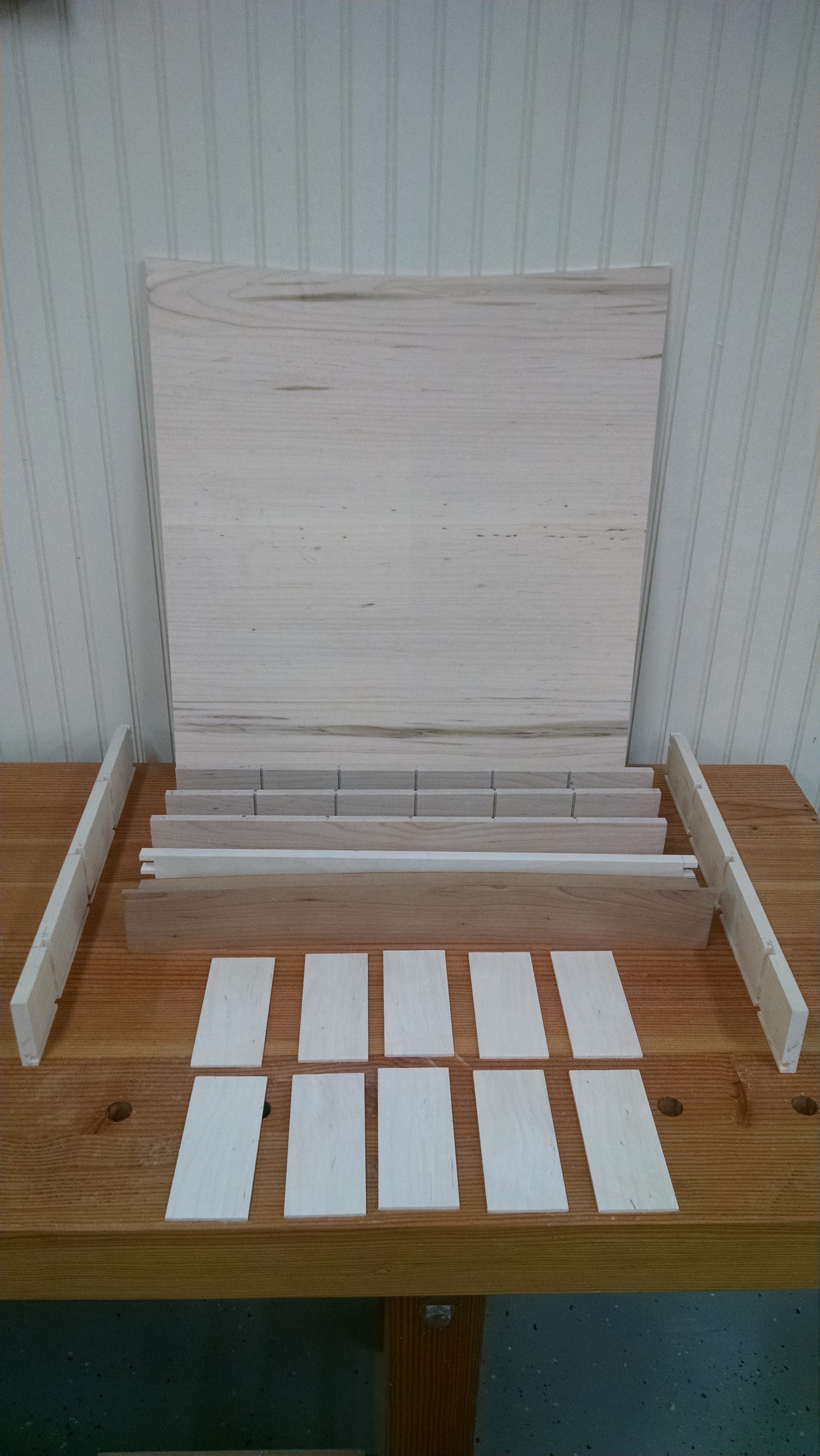

My curved-front desk project came to a close over the holidays. It was a long and complex project, and I have a lot of memories stored up in it. My projects act like a real-world version of Professor Dumbledore’s Pensieve. Every piece of the project triggers a vivid recollection of my state of mind, surroundings, and worries at the time that I made it. It’s a lot like hearing a song from years ago that instantly transports you back to that time in your life.

When I run my hands along the sweep of the legs I remember how hot it was the day that I cut the curves. I was listening to Fleet Foxes on repeat and I nicked my finger on the blade of my spokeshave. The dovetail joinery between the front rails and the drawer dividers reminds me of how sick I was when I cut those joints. I can pinpoint the exact spot where I stopped mid-saw cut to go to the hospital. Seeing the aprons joined to the legs brings back a vivid memory of complete joy when the joints slide together perfectly with minimal trimming of the tenons. The drawers remind me of the despair I felt as I struggled to motivate myself to finish them over multiple consecutive Sundays, with my Chicago Bears losing on the TV in my shop and autumn rain pouring down outside. And the top will forever remind me of the day that I explained to my eight-year-old daughter how the front edge would mirror the curve of the front of the carcase and she sighed, nodded, and said, “That sounds nice, but why don’t you just leave it square so it’ll be done already?”

A hand-made piece of furniture isn’t just some planks of wood stuck together. Its a culmination of dozens of hours of work and thousands of decisions. Everything I’ve ever made is a physical representation of that period of my life capable of transporting me back through time. And that is one thing I know I’ll never get from a store-bought piece of furniture.